By Kayla Matthews,

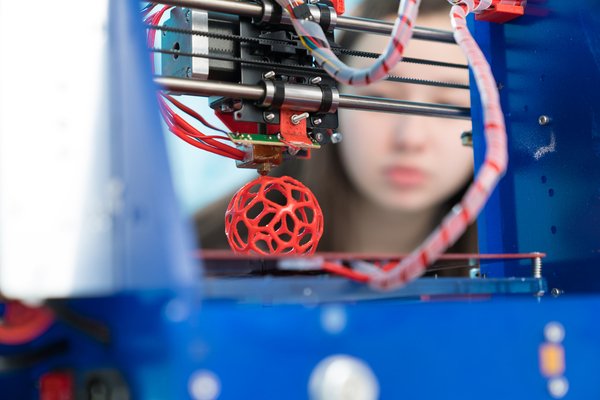

Like any new technology, there’s always a lot of hype surrounding its release. Everyone sees it as “the next best thing” and the solution to all of their problems. 3D printers certainly fit the mold, so to speak.

Consumers initially saw 3D printers as a “factory in every home,” but they soon came to realize that the items they produced weren’t functional. As the hype fizzled out, new fears emerged in the manufacturing segment, and some companies using 3D printers saw year-over-year declines in their revenue. The rise and fall of additive manufacturing took place over a few short years, but that wasn’t the end of the story.

Additive manufacturing is on an upward trajectory as of late. This resurgence is due to the fact that the list of possible 3D-printable materials has more than doubled in the last five years.

The increasing adoption of mixed-material printers is another reason for the return of 3D printers, as they were initially unable to create parts from more than one material. This is no longer the case, and it seems almost certain that additive manufacturing is here to stay.

Furthermore, there are many signs that point to investments in additive manufacturing increasing in 2020 due to the increased capabilities, the expanded applications and the shift towards a greener economy.

Increased Capabilities of Additive Manufacturing

The 3D printers available today are now capable of printing a wider variety of materials than ever before. Naturally, there’s going to be more and more metal 3D printing. Newer machines can also print faster, which will allow manufacturers to be more productive and lower their costs. Increasing the speed of the machines is a huge step in the right direction, and it will need to continue to increase to keep additive manufacturing around for the long haul.

One of the more significant downfalls of the technology is the speed that it takes to manufacture a product, so this is a major step in the right direction. What’s more, the size of printable objects is currently growing. This rise in the “build volume” will increase the amount and complexity of projects that the machines can tackle.

Expanded Applications of Additive Manufacturing

With the increased capabilities of 3D printers, there’s likely going to be more industries adopting the technology. The aerospace industry has already taken notice, with companies like Airbus and Boeing choosing to implement additive manufacturing into their core manufacturing strategy. Other large sectors such as the automotive, dental and healthcare industries have started using these technologies as well.

They’ve committed time and research to more effectively integrate the technology. For example, companies in the medical field are beginning to manufacture 3D-printed braces and custom-molded assistive devices. 3D-printed medical devices and prosthetics are more than likely on their way with help from the additive manufacturing process.

Dean Franks, the head of global sales at the additive manufacturing company, Autodesk, believes that consumer products, industrial machinery, automotive and tooling applications are the growth opportunities for additive manufacturing. He believes that these industries will start to grow as the more established aerospace, medical and dental markets continue to grow.

Bertrand Humel van der Lee, the Chief Customer Operations Officer at EOS, predicts that 3D printing within healthcare will flourish because there is an increase in demand for personalized healthcare, treatments, and medical devices.

There are many applications for this technology, and it is evident that new and improved applications will continue to emerge and enjoy investment.

A Sustainable Option for Manufacturing

China initially began investing in additive manufacturing, partly because it’s a greener technology than most other manufacturing methods. Since China relies heavily on raw materials and fuel to produce their goods, anything that could help them reduce their usage of oil and gas was a significant opportunity.

Additive manufacturing can also lower costs for manufacturers, allowing them to automate repeatable tasks to complete them in a more efficient manner. Reducing costs and increasing efficiency through a more sustainable process will also free up time and money, which a company can then dedicate to implementing more sustainable practices in the manufacturing process.

Current and Future Investments

The past and continual growth of this technology, the expanding applications and the sustainability of this manufacturing method all support the value of additive manufacturing as an investment opportunity in 2020 and beyond. Large companies like General Electric and Berkshire Hathaway have both made substantial investments into the industry, reflecting their trust in the growth of this segment.

These bold investments give smaller manufacturers the confidence they need to take the next step in making an investment.

The smaller companies may have been hesitant to invest since the future is still unknown, but they no longer have to risk it all on their own, as they’ve seen larger corporations commit. This gives them a sense of confidence in the technology and the future of additive manufacturing.

This article originally appeared on our sister site, ETF Trends.